AI-Powered PPE Detection Solutions

AI-driven PPE detection technology uses deep-learning algorithms to automatically spot and notify about any safety gear violations, helping you keep your workforce safe and comply with safety rules.

Why Choose AI-Driven PPE Detection?

AI-powered PPE compliance technology uses state-of-the-art algorithms, video analytics, and computer vision to ensure:

Leverage AI-driven PPE detection to ensure employees wear the required safety gear, reducing accident risks and liabilities. Our advanced system helps you maintain compliance with safety regulations and reduces the risk of workplace injuries.

Our system promptly identifies non-compliance, enabling corrective actions to improve overall workplace safety. By automatically detecting missing or improperly worn PPE, you can address issues immediately and prevent accidents before they happen.

Automated detection saves time and resources while maintaining consistent safety standards. Our system continuously monitors your workplace, ensuring that safety protocols are always followed.

Tailored detection solutions ensure seamless integration into specific safety protocols. Whether you need to monitor a construction site or a healthcare facility, our system can be customized to meet your unique needs.

Our clients: ![]()

Elevate Workplace Safety with Our Proven Expertise

Join top companies in using our cutting-edge AI – driven PPE detection system to enhance safety in high-risk environments.

Industries Using AI-PPE Detection

Our technology helps many industries, from factory workers to hospital staff, stay safe by checking their protective gear.

Construction

Real-time AI – driven safety checks ensure workers wear proper gear on construction sites.

Hard hats, high-visibility vests, safety goggles, fall protection harnesses, safety gloves, steel-toe boots, dust masks, ear protection, and reflective clothing.

Manufacturing

AI enhances safety in manufacturing facilities by accurately detecting PPE usage.

Safety goggles, gloves, ear protection, face shields, steel-toe boots, hard hats, aprons, protective suits, and respirators.

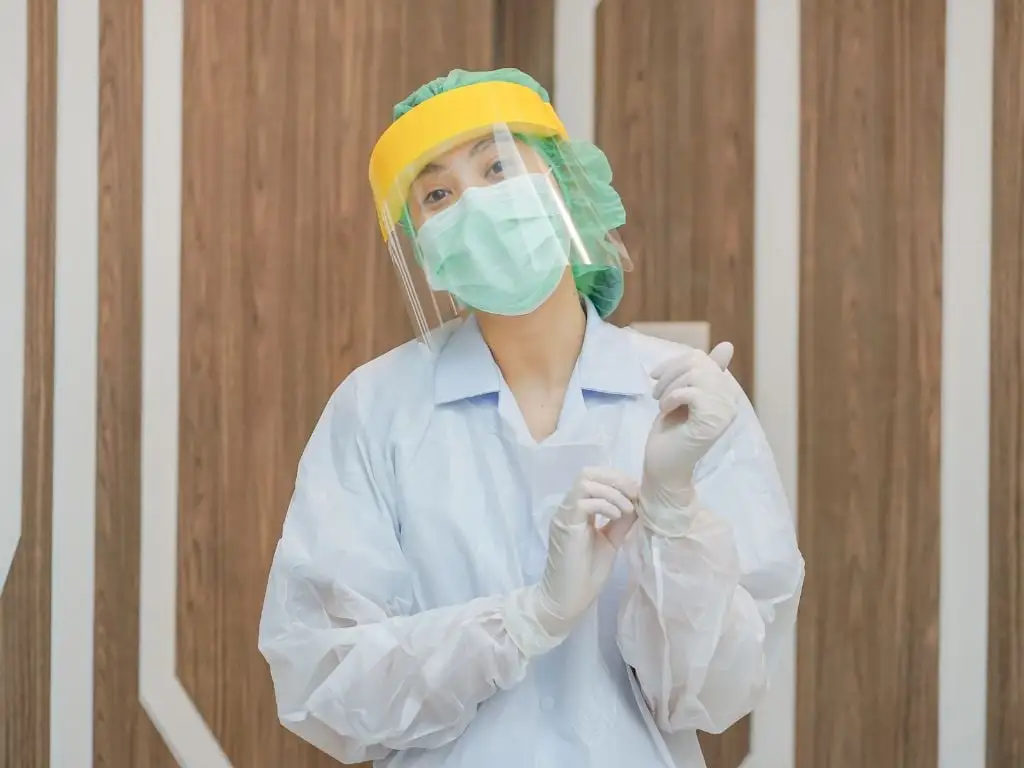

Healthcare

Ensuring healthcare workers wear proper safety gear to control infections and stay safe.

Surgical masks, gloves, face shields, gowns, N95 masks, safety goggles, shoe covers, hair nets, and hazmat suits.

Oil & Gas

Automated AI inspections improve safety in the industry, enforcing guidelines for PPE usage.

Hard hats, flame-resistant clothing, safety goggles, ear protection, safety boots, gloves, respirators, full-body suits, and face shields.

Flexible Pricing Packages

We offer competitive and transparent pricing plans designed to fit your needs.

Starter

Pro

Custom

PPE Detection Integration Workflow

Our integration workflow uses advanced AI algorithms, seamless camera integration, and instant notifications for better safety in high-risk areas.

Camera Integration

During the initial setup phase, our PPE detection software connects with your existing cameras to train the model, ensuring accurate and reliable detection.

AI Analysis

Powerful AI algorithms analyze the footage to find people and see if they are wearing the required safety gear.

Alerts and Reporting

The system sends alerts so you can fix them right away. Detailed reports help you keep track of safety.

PPE Video Analytics Features

Our PPE Video Analytics system offers advanced features to ensure workplace safety and compliance with minimal effort:

Frequently Asked Questions

Explore answers to frequently asked questions about PPE violation detection system, covering functionality, compatibility, and implementation.

PPE detection is a technology that integrates with existing cameras for real-time monitoring and analysis to ensure that individuals are wearing the necessary protective gear. Our system uses advanced algorithms to detect PPE such as hard hats, safety glasses, gloves, masks, and high-visibility vests.

It enhances workplace safety by ensuring compliance with safety regulations, monitoring PPE usage, and sending real-time notifications for EHS professionals to prevent potential hazards and protect workers in hazardous environments.

System detect various types of PPE including wearing hard hats, vests, safety glasses, safety helmets, high-visibility vests, and aprons, among others, to ensure the proper use of PPE in the workplace.

Yes, this technology can be used for workers working at heights by accurately monitoring PPE usage, ensuring workers are wearing proper PPE, and sending real-time notifications to protect against potential hazards.

In the context of workplace safety, Artificial Intelligence (AI) plays a pivotal role in Personal Protective Equipment (PPE) detection through the application of sophisticated machine learning algorithms, primarily Convolutional Neural Networks (CNNs). These algorithms are trained on large datasets of annotated images to recognize various types of PPE, such as helmets, goggles, and vests. Once trained, the AI system can process live video feeds from the workplace, accurately detecting and classifying the presence or absence of PPE on individuals in real-time. This automatic detection facilitates proactive safety management, enabling immediate response to PPE non-compliance and thereby significantly reducing the risk of workplace injuries and ensuring safe work environment.

AI PPE Detection helps with OSHA compliance and audit processes by providing automated PPE detection, ensuring proper PPE use, and maintaining compliance with safety regulations, which can aid in the audit of safety practices and monitoring PPE usage for regulatory compliance.

An object detection models fundamentally comprises high-quality data input, advanced deep learning algorithms, a comprehensive training dataset, and robust hardware and software for real-time processing and alerting.

Let’s Talk About Workplace Safety With AI-Driven PPE Detection System

Elevate workplace safety standards and comply with safety laws effortlessly.

Contact our team to embrace our AI-driven PPE detection technology and take a proactive approach to protect your workers.

Lukas Vaznelis

Business Development Manager