AI-driven PPE systems are transforming construction site safety by leveraging advanced algorithms and real-time monitoring to guarantee compliance and reduce risks.

These systems integrate with existing camera infrastructures to continuously track PPE usage, instantly alerting managers and workers to any non-compliance issues. Benefits include heightened safety, reduced accident rates, and potential insurance premium savings.

Discover more about the innovative impact and case studies demonstrating AI-driven PPE success.

The Current State of PPE in Construction Industry

Traditionally, personal protective equipment (PPE) on construction sites has relied heavily on manual oversight and worker compliance. Construction workers are required to adhere to workplace safety regulations by using PPE such as helmets, gloves, and safety vests. Supervisors typically conduct periodic checks to verify PPE compliance, aiming to mitigate safety violations and protect workers from potential hazards. These traditional methods, however, present significant limitations and challenges.

One major challenge is the reliance on human supervision to verify compliance. Supervisors may miss violations due to the vastness of construction sites and the sheer number of workers involved. This manual oversight is not only labor-intensive but also prone to human error. Additionally, construction workers might occasionally neglect proper PPE usage, either due to discomfort or lack of awareness, leading to increased risks of accidents and injuries.

Another limitation lies in the documentation and reporting processes. Traditional methods usually involve manual record-keeping, which can be cumbersome and inefficient. This makes it difficult to track compliance trends over time, identify recurring safety issues, or implement timely corrective measures. Consequently, these challenges highlight the need for more efficient and accurate solutions to enhance workplace safety.

AI-Driven PPE for Construction Sites: How it Works

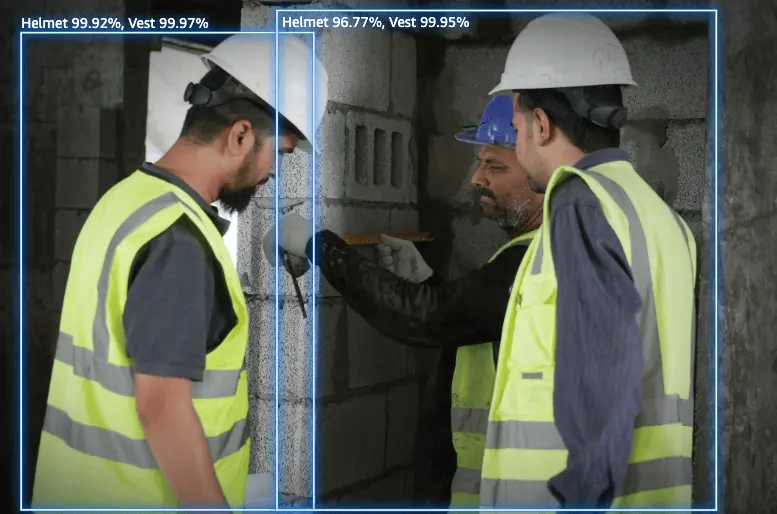

Addressing the limitations of traditional PPE oversight, AI-driven PPE detection technology leverages advanced algorithms and computer vision to guarantee real-time compliance on construction sites. This ai-powered PPE detection system integrates seamlessly with existing camera infrastructures, capturing and analyzing images at regular intervals to monitor the correct usage of personal protective equipment (PPE) such as helmets and vests.

Upon detecting non-compliance, the system generates real-time alerts for site managers and workers. These immediate notifications enable swift corrective actions, thereby improving safety measures and reducing the risk of workplace accidents. The technology categorizes individuals based on their level of protection—protected, partially protected, or unprotected—facilitating targeted interventions to address specific safety concerns effectively.

Moreover, data visualization features of these systems provide project managers with insightful compliance trends through detailed charts and reports. This allows for informed decision-making and improves adherence to safety protocols over time. For instance, the OpticVyus AI solution exemplifies such capabilities by offering extensive oversight and actionable insights into PPE usage on construction sites. Fundamentally, AI-driven PPE detection systems represent a significant advancement in ensuring occupational safety and compliance in the construction industry.

Benefits of AI-Driven PPE

Leveraging AI-driven PPE detection systems offers notable benefits, including improved real-time safety monitoring and reduced workplace accidents on construction sites. Through real-time AI capabilities, these systems continuously scan the environment to guarantee that workers are adhering to PPE compliance standards, considerably mitigating safety hazards. This proactive approach to safety management can drastically reduce the incidence of workplace accidents by providing immediate alerts for any non-compliance, thereby fostering a safer construction environment.

One of the primary advantages of AI PPE detection is the automation of monitoring processes. This not only streamlines inspections but also saves valuable time and resources for safety managers and site supervisors. The advanced algorithms employed in these systems guarantee precise recognition of essential PPE gear such as helmets and vests, which is vital for maintaining compliance with stringent safety regulations.

Furthermore, companies that integrate AI-driven PPE solutions can potentially lower their insurance premiums due to a decreased risk of accident claims, boosting overall financial sustainability. Additionally, the presence of robust safety monitoring can contribute to a positive safety culture on construction sites. Workers feel more secure knowing that their well-being is continuously monitored and enforced, improving overall workers’ safety.

Case Studies and Examples

A compelling illustration of the effectiveness of AI-driven PPE detection systems is seen in a construction company that experienced a 40% reduction in safety violations within the first three months of deployment. This notable improvement underscores the importance of PPE and the role advanced technology plays in improving construction safety. By implementing an AI-driven PPE detection solution, the company could provide an immediate response to non-compliance, thereby ensuring that workers adhered to safety regulations consistently.

Another case study from a large manufacturing facility revealed a 30% decrease in workplace injuries due to improper gear usage, thanks to real-time monitoring. This highlights how AI solutions contribute greatly to compliance with safety regulations and overall worker safety. In a similar vein, a construction site utilizing AI cameras reported a 50% drop in insurance claims related to PPE non-compliance over a year, resulting in substantial cost savings.

Future of AI-Driven PPE in Construction

Anticipation of technological advancements in AI-driven PPE systems heralds a transformative era in construction site safety management. As these systems become more sophisticated, they promise to redefine how workplace safety is guaranteed within the construction industry. Future developments in AI and PPE detection will likely introduce improved capabilities that further mitigate safety breaches and reduce accident rates.

- Real-Time Data Analytics: AI systems will provide more in-depth real-time analytics, allowing for immediate identification and correction of non-compliance with PPE regulations. This rapid response can greatly curtail potential safety breaches.

- Integration with Other Safety Technologies: The incorporation of AI-driven PPE detection with other emerging safety technologies, such as worker density management and environmental sensors, will create a more thorough safety ecosystem on construction sites.

- Predictive Safety Measures: Leveraging historical data, AI can predict potential areas of risk and suggest proactive measures to prevent accidents, thereby improving overall workplace safety.

- Scalable Solutions: As AI technology advances, scalable PPE detection systems tailored to various sizes and types of construction projects will become more accessible, facilitating broader adoption across the industry.

These advancements in AI-driven PPE technology are poised to bring about a new standard of safety in the construction industry, fostering a culture of proactive and data-driven safety management.

Conclusion

The integration of AI-driven PPE in construction is a significant advancement in ensuring worker safety. This technology enables us to monitor and manage construction sites more effectively, streamlining processes and reducing manual labor.

With AI-driven PPE, we can ensure compliance with safety regulations, minimizing the risk of accidents and injuries. While there may be challenges ahead, the future of construction looks promising. This innovative technology has the potential to transform the industry, ensuring every worker returns home safely and every construction site is a safe environment.

Not Sure How AI Can Help Your Business? Let’s Talk!

Ugnė Daniūnaitė

Business Development Manager

Book a no-obligation free consultation with our expert.