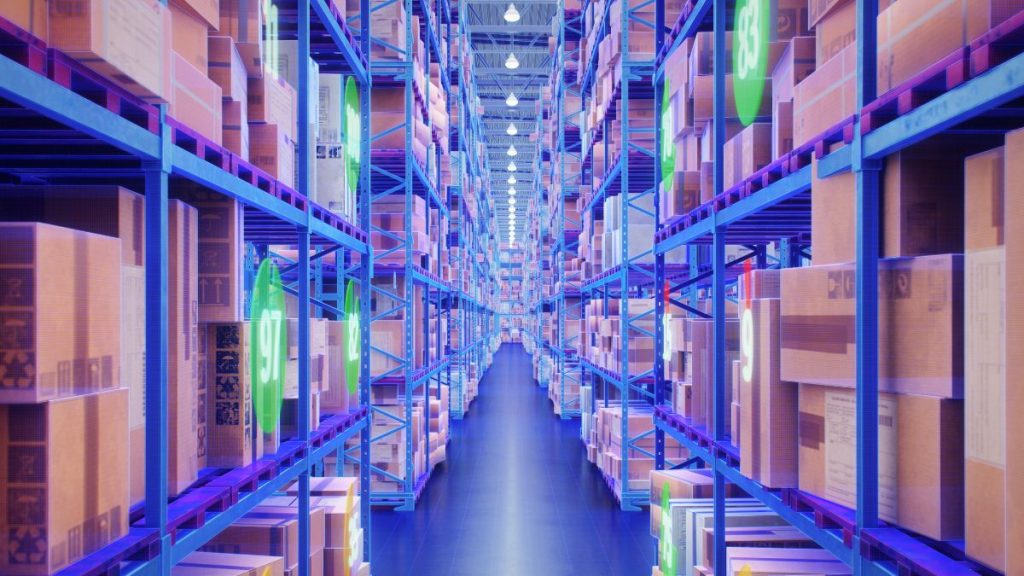

In an era where technology reshapes our daily lives, warehouses, the backbone of global commerce, are undergoing a significant transformation.

The integration of artificial intelligence (AI) is not just a trend but a revolution in efficiency and productivity. This evolution is crafting smarter, more adaptive, and safer environments for goods storage and distribution.

As we delve into the groundbreaking trends powered by these technologies, we’re not merely observing an upgrade in warehouse management; we’re witnessing a leap towards futuristic logistics.

This journey through technological innovation showcases how the synergy of AI and automation is setting new standards, ensuring that the warehouses of today are ready for the challenges of tomorrow.

Operational Efficiency and Productivity

1. Pallet Tracking

Advanced tracking systems, using computer vision, RFID and IoT, enable precise monitoring of pallet locations, improving retrieval times, theft monitoring and reducing misplacements.

2. Inventory Management

AI algorithms analyze historical data to predict stock levels, automate reordering, and optimize inventory layout, minimizing overstock and stockouts.

3. Workflow Optimization

Machine learning models identify bottlenecks and inefficiencies in workflows, suggesting optimizations for enhanced productivity.

4. Load Optimization

AI-driven software calculates the most efficient loading patterns for trucks and containers, maximizing space utilization and reducing shipping costs.

5. Robotic Picking and Sorting

Robots equipped with computer vision and machine learning algorithms automate picking and sorting tasks, increasing speed and accuracy while reducing human error.

6. Automated Guided Vehicles (AGVs) Navigation

AGVs use AI for dynamic navigation around warehouses, avoiding obstacles and optimizing routes in real-time.

7. Space Utilization Analysis

Machine learning models analyze space usage patterns to recommend storage configurations that maximize warehouse space efficiency.

8. Supply Chain Visibility

AI and IoT provide end-to-end visibility of the supply chain, enabling predictive adjustments to meet demand and reduce downtime.

9. Predictive Analytics for Workflow Optimization

AI analyzes data to predict future trends, allowing for proactive workflow adjustments that improve efficiency and productivity.

10. 3D Mapping and Space Optimization

AI-powered 3D mapping technologies assess warehouse layouts, suggesting optimizations for space usage and storage arrangements.

11. Enhanced Object Tracking for Dynamic Environments

Computer vision and IoT enhance tracking capabilities, allowing for real-time monitoring of objects in dynamic warehouse environments.

Safety and Compliance

12. Worker Safety Monitoring

AI and IoT devices monitor worker movements and environmental conditions to prevent accidents and ensure a safe working environment.

13. PPE Compliance

Computer vision systems ensure that workers comply with personal protective equipment (PPE) regulations, enhancing workplace safety.

14. Fire and Hazard Detection

AI-powered sensors detect potential fire and hazard risks, providing early warnings to prevent accidents and ensure compliance with safety standards.

15. Human-Robot Collaboration

Cobots equipped with advanced sensors and AI work alongside humans, enhancing safety and efficiency through precise and intelligent assistance.

16. Real-time Alerts for Policy Violations

AI systems monitor operations in real-time, sending alerts for any detected policy or compliance violations, ensuring immediate corrective action.

17. Compliance Monitoring

Computer vision and AI algorithms ensure that warehouse operations adhere to regulatory and compliance standards, reducing the risk of fines and legal issues.

18. Behavior Analysis for Efficiency and Safety

Machine learning models analyze worker behaviors to identify unsafe practices and inefficiencies, providing insights for training and improvement.

Technology-Enhanced Control and Security

19. Gesture Control for Machinery

Advanced gesture recognition technologies allow operators to control machinery with simple hand gestures, improving efficiency and safety.

20. Access Control

AI-enhanced systems with facial recognition or biometrics secure access to sensitive areas, ensuring that only authorized personnel can enter.

21. Vehicle and Equipment Tracking

IoT and AI provide real-time tracking of vehicles and equipment, enhancing operational control and preventing unauthorized use.

22. Theft and Intrusion Detection

AI-powered surveillance systems detect unusual activities, providing immediate alerts to prevent theft and unauthorized access.

23. Smart Security Systems

Integrated AI security systems offer comprehensive protection, combining access control, surveillance, and intrusion detection for heightened warehouse security.

24. Equipment Health Monitoring

IoT sensors and AI algorithms monitor equipment health, predicting failures before they occur and scheduling maintenance to avoid downtime.

25. Predictive Maintenance

Machine learning analyzes equipment data to predict maintenance needs, ensuring optimal performance and reducing repair costs.

26. Fraud Detection

AI algorithms detect patterns indicative of fraud in inventory management and shipping processes, protecting assets and financial integrity.

27. Asset Tracking and Management

Advanced tracking systems, integrating RFID and IoT, offer real-time visibility of assets, improving management and reducing losses.

Quality Assurance and Product Handling

28. Automated Quality Control

Computer vision systems inspect products for defects, ensuring high quality and reducing manual inspection needs.

29. Smart Package Inspection

AI-driven image recognition checks packaging and labeling for accuracy, enhancing compliance and customer satisfaction.

30. Intelligent Product Recognition

Enhanced barcode and RFID technologies with machine learning improve product sorting, identification, and inventory accuracy.

31. Enhanced Inspection Systems

Multispectral imaging and AI detect imperfections or contaminants, ensuring product quality beyond human capabilities.

Innovative Applications of IoT and Computer Vision

32. Real-time Inventory Updates

IoT devices provide immediate updates to inventory levels, enabling accurate stock management and reducing discrepancies.

33. Temperature and Environmental Monitoring

IoT sensors and AI dynamically monitor and adjust conditions, ensuring optimal storage environments for perishables.

34. AI-Driven Energy Management

Machine learning optimizes energy consumption across warehouse operations, reducing costs and environmental impact.

35. Automated Lighting Systems

IoT and AI adjust lighting based on activity and occupancy, enhancing efficiency and safety.

36. Flow Optimization

Computer vision and AI analyze goods and personnel movement, optimizing flow to reduce bottlenecks and improve safety.

37. Environmental Impact Monitoring

AI and IoT monitor and analyze the environmental impact of warehouse operations, supporting sustainability goals.

38. Smart Waste Management

Sensor-based systems and AI optimize waste sorting and recycling processes, aligning with environmental responsibility.

Worker Experience and Training Enhancements

39. Enhanced Worker Assistance

AR provides workers with real-time information overlays, aiding in task completion and reducing errors.

40. Voice-Activated Controls

Advanced voice recognition allows for hands-free operation of systems, enhancing efficiency and safety.

41. AR Integration for Training

AR technologies offer immersive training experiences, providing interactive learning environments for workers.

42. Interactive Training Modules

VR and machine learning create detailed training simulations, speeding up skill acquisition and enhancing safety education.

43. Collaborative Robotics (Cobots) Enhancement

Cobots with advanced vision systems work alongside humans, offering precision and reducing strain.

Conclusion

AI-driven warehouse trends reveal more than just the technological prowess at our disposal; it highlights a shift towards a more intelligent, efficient, and sustainable model of warehouse management. As we use the power of AI, we’re not just optimizing space or streamlining operations; we’re reimagining what’s possible in the realm of logistics.

This new era of warehouse operation, marked by enhanced safety, productivity, and environmental responsibility, is not a distant future but an unfolding reality. By embracing these advancements, the logistics sector is not only addressing today’s challenges but is also paving the way for a smarter, more resilient supply chain infrastructure.

Not Sure How AI Can Help Your Business? Let’s Talk!

Lukas Vaznelis

Business Development Manager

Book a no-obligation free consultation with our expert.