Embrace the future of solar farm inspections with AI drone technology. Opt for efficient defect detection and substantial cost reduction.

Drones are 50 times faster than manual inspections, using advanced imaging like thermal technology.

Detect cracks, soiling impact, PID effects, connector issues, and shading losses swiftly. These drones guarantee peak performance and safety, maintaining efficiency through timely maintenance.

Maximize energy output and ROI, ensuring long-term panel health. Explore the domain of AI and drones improving solar farm operations. In this evolving landscape, enhance efficiency and accuracy for best solar panel performance.

Drones Ensure Operational Efficiency

According to U.S. EIA, there are more than 2.500 utility-scale solar farms in the US alone. As with any other infrastructure, regular inspection and maintenance becomes a cumbersome task for such vast areas.

Investing in AI drone technology for solar farm inspection is transforming the industry by improving efficiency and reducing costs. The market potential for AI drone solar farm inspection is substantial, driven by the need for efficient defect detection.

By utilizing advanced imaging technologies and AI algorithms, these drones can swiftly detect defects, malfunctions, and areas of inefficiency in solar panels. This efficient defect detection not only reduces costs but also leads to improved maintenance practices. Companies investing in AI drone technology aim to enhance operational efficiency, gaining a competitive edge in the market.

The global market for AI drone solar farm inspection is on a significant growth trajectory, reflecting the industry’s shift towards innovative inspection solutions. These investments not only optimize energy production but also contribute to the long-term sustainability of solar farms.

As more companies recognize the benefits of AI-powered drone inspections, the industry is poised for further advancements in operational efficiency and maintenance practices.

Manual Vs Drone Inspection

Utilizing drone technology for solar panel inspections greatly improves efficiency and safety compared to traditional manual methods.

Drone inspections are 50 times faster than manual inspections, notably reducing the time required for thorough assessments.

By leveraging advanced imaging technologies like thermal imaging, drones can detect defects and areas of inefficiency swiftly and accurately, optimizing the overall inspection process.

Additionally, drones provide a safer environment for surveying, mitigating risks associated with manual inspections and ensuring the well-being of personnel.

In terms of cost-effectiveness, UAV technology substantially reduces inspection and maintenance costs when compared to traditional methods.

The data collected by drones can be stored, tracked, and analyzed for future reference, streamlining the maintenance processes and allowing for proactive identification of issues.

This not only optimizes the performance of solar panels but also minimizes downtime and maximizes energy production efficiency in solar farms.

Types of Solar Defects Detected

From crack detection methods to soiling impact analysis and PID effect monitoring.

Understanding these defect types is essential for optimizing energy production and ensuring the longevity of solar panels.

Crack Detection Methods

Essential for identifying cracks, visual inspection plays a fundamental role in detecting defects that can impact the efficiency of solar panels in large-scale solar farms.

When it comes to crack detection methods, thermal inspections are highly effective. Electroluminescence technology is adept at mapping out photo emissions to pinpoint cracks in solar panels accurately.

Infrared thermography, utilizing an infrared camera, captures heat radiation signatures to identify cracks in solar panels on a large scale.

Drone inspection equipped with thermal cameras offers a thorough approach to crack detection in solar panels, ensuring early identification to prevent energy output loss.

These advanced methods are essential for maintaining the peak performance of solar panels, ultimately maximizing energy production in solar farms.

Soiling Impact Analysis

An in-depth analysis of the impact of soiling on solar panels reveals various types of defects that can greatly affect energy output efficiency. Soiling analysis is essential for measuring the decrease in power output caused by dirt accumulation on the panels.

Techniques such as spectral analysis and weather monitoring play an important role in evaluating the extent of soiling on solar panels. By implementing automated cleaning systems, the effects of soiling on solar panel performance can be minimized, ensuring efficient energy production.

Regular maintenance is necessary to mitigate the impact of soiling, as it can reduce energy output by up to 25%. Monitoring and addressing soiling issues promptly are key to maximizing the efficiency and longevity of solar panels.

PID Effect Monitoring

When monitoring PID effects in solar panels, common defects like cell mismatch, cracks, discolorations, delaminations, and hotspots have a significant impact on efficiency. Thermal inspection techniques using drones equipped with thermal cameras play an important role in identifying these defects.

By capturing heat radiation through infrared thermography, these drones can detect anomalies in solar panels without causing any damage. The thermal images obtained provide valuable insights into the health of the solar panels, enabling timely maintenance to maintain peak performance.

With the ability to conduct non-destructive inspections on a large scale, drone thermal inspections offer a thorough solution for monitoring and addressing defects in solar panels efficiently.

Connector Deterioration Identification

Connector deterioration in solar panels poses a critical risk to efficiency and safety, necessitating proactive identification and mitigation strategies. Types of defects such as corrosion, loose connections, and physical damage can compromise the performance of the solar panel system.

Detecting connector deterioration is crucial for maintaining peak solar panel efficiency and preventing power loss. Regular inspection of connectors is essential to guarantee the smooth operation of the solar farm.

Drone inspections utilizing AI technology offer a precise and efficient method to identify connector defects accurately. By leveraging advanced imaging technologies and AI algorithms, these inspections can swiftly pinpoint issues, enabling timely maintenance actions to be taken to uphold the performance and safety of the solar panel system.

Shading Loss Evaluation

Detecting shading loss in solar panels is essential for optimizing energy production efficiency and maximizing ROI in solar farm operations. Shading loss, often caused by obstructions like trees or buildings, reduces energy production efficiency in affected solar cells, impacting overall system performance.

Evaluating shading loss involves identifying specific areas where shadows affect solar panel output. Techniques such as solar path mapping and shading analysis software are utilized to determine the extent of shading impact accurately. By promptly addressing shading losses through these methods, solar farm operators can effectively optimize energy production and maximize ROI.

It’s vital to employ these advanced tools and strategies to ensure that solar panels operate at their maximum potential and contribute significantly to the overall efficiency of the solar farm.

AI Techniques for Solar Farm Inspection

AI drone inspection of solar farms is a sophisticated application that combines drone technology with advanced artificial intelligence to monitor and maintain the health of solar panels.

This process significantly improves efficiency and accuracy compared to manual inspections. Here’s a deeper look at the technical aspects:

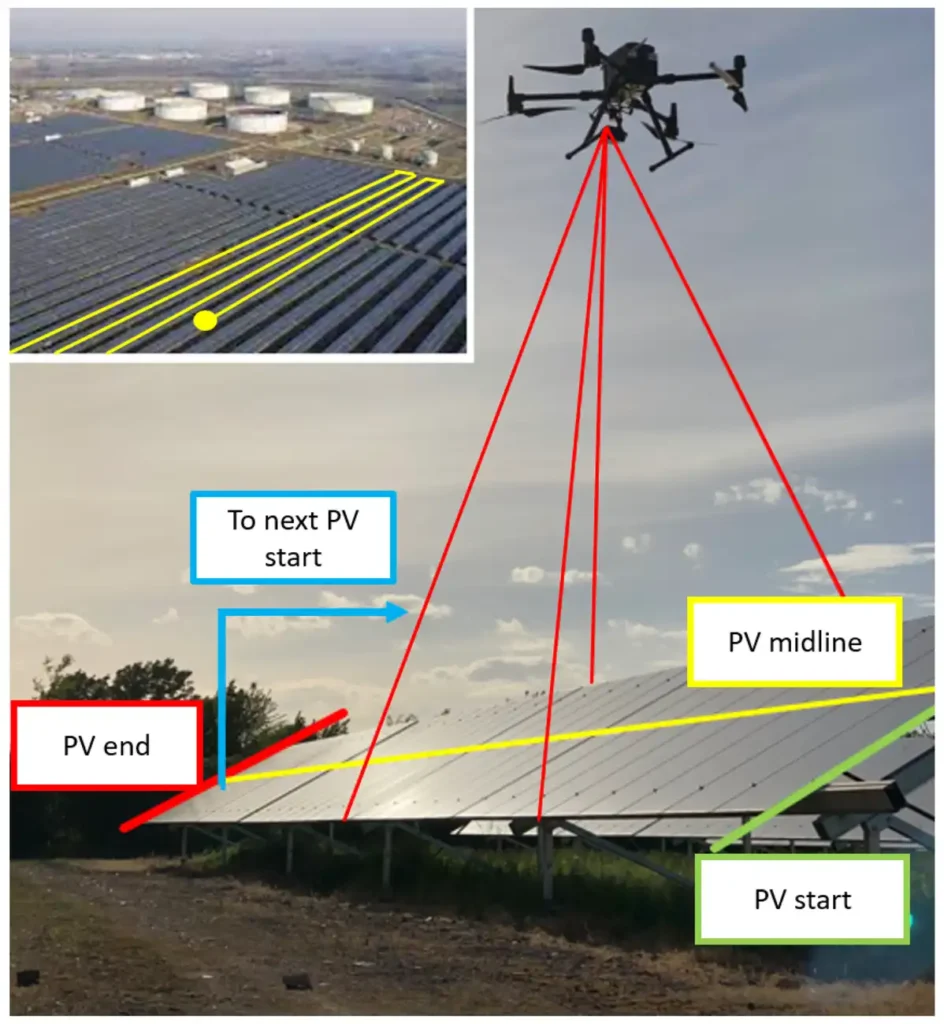

Drone Technology

Drones equipped with high-resolution cameras and other sensors such as infrared or thermal imaging fly over solar farms. These drones can cover large areas quickly and capture detailed images that are critical for inspection.

AI Models Used

- Image Recognition Models: Convolutional Neural Networks (CNNs) are commonly used for image recognition tasks. These models detect anomalies and classify them into categories such as dirt, cracks, or malfunctioning cells. Popular architectures might include ResNet, Inception, or custom architectures tailored for specific types of image data.

- Object Detection Models: These models pinpoint the exact location of defects or anomalies on the solar panels. Models like YOLO (You Only Look Once), SSD (Single Shot MultiBox Detector), or Faster R-CNN are used to detect objects within images.

- Thermal Image Analysis: For analyzing thermal images, AI models are trained to identify heat signatures that indicate malfunctioning or inefficient panels. These can be specialized versions of CNNs designed to interpret the specific patterns visible in thermal imaging.

- Predictive Maintenance: Using historical data and machine learning algorithms such as regression models, random forests, or neural networks, AI can predict potential future failures or suggest maintenance activities.

Data Processing and Analysis

Drones collect vast amounts of data, which need to be processed efficiently. This involves pre-processing steps such as normalization, background subtraction, and sometimes augmentation to enhance the dataset quality.

The AI models are trained on labeled datasets where anomalies are marked and categorized. The training involves adjusting the model parameters to minimize error on this training dataset. Validation datasets help in tuning the models without overfitting them to the training data.

In some advanced setups, AI processing can be done on the drone itself (edge computing), allowing for real-time decision-making. This requires lightweight models or efficient processing capabilities on the drone.

Integration and Automation

The AI models are integrated with drone navigation and data capture systems, allowing for automated flight paths that optimize coverage and data collection. AI systems can automatically generate reports highlighting problem areas, their severity, and recommended actions. This helps in quick decision-making and maintenance planning.

Challenges and Considerations

Ensuring high accuracy in diverse lighting and weather conditions can be challenging. As drones collect sensitive data, ensuring this data is securely handled and processed is crucial. Complying with airspace regulations and data protection laws is necessary for operating AI-equipped drones.

Automating Aerial Footage Analysis

Yet acquiring inspection footage is only one part of the job – and drones are very efficient at doing that.

The larger problem lies with inspection footage analysis. Just imagine having to review aerial footage of a 2.500 acre solar farm. Thus companies are turning to computer vision software to automate aerial footage analysis and improve their processes up to 20 times.

Computer vision software uses object detection and AI analysis to spot defects and imperfections, highlight trends or identify anomalies which can be invisible to the naked eye. In addition, it can crunch vast amounts of data in no time.

EasyFlow provides specialized aerial footage analysis models for solar farm operators, as well as third party UAV operators engaged in energy site inspection. The service is available all over the world – you only have to upload the footage for the analysis.

Conclusion

You now understand the immense potential of AI drone technology in transforming solar farm inspections.

By utilizing cutting-edge imaging tools and advanced AI algorithms, these drones can swiftly and accurately identify defects, malfunctions, and areas of inefficiency in solar panels.

This innovative approach not only guarantees peak energy production levels but also allows operators to proactively address issues and maintain peak performance.

Looking for ways to make your renewable energy production more efficient? Let’s talk.

Not Sure How AI Can Help Your Business? Let’s Talk!

Lukas Vaznelis

Business Development Manager

Book a no-obligation free consultation with our expert.