Ortho Baltic, one of Europe’s largest orthopedic device manufacturers, sought to revolutionize the process of developing patient-specific implants.

Traditionally, qualified engineers manually reconstructed personalized 3D anatomical models from Computer Tomography (CT) images, which involved extensive time and effort to clean the data from metal artifacts and mark anatomical features.

To enhance efficiency and accuracy, Ortho Baltic collaborated with EasyFlow, an expert in AI and Computer Vision, and renowned for its exceptional MLOps services, to develop an automated data-driven model for implant production.

The Challenge

CT images used for implant development often contain significant noise from metal artifacts, making the process of identifying anatomical landmarks and clinical reference points time-consuming and prone to inaccuracies.

Cleaning up the CT images and marking anatomical features required considerable expertise, with an average skilled specialist spending 3 hours on a single 3D case.

The Solution

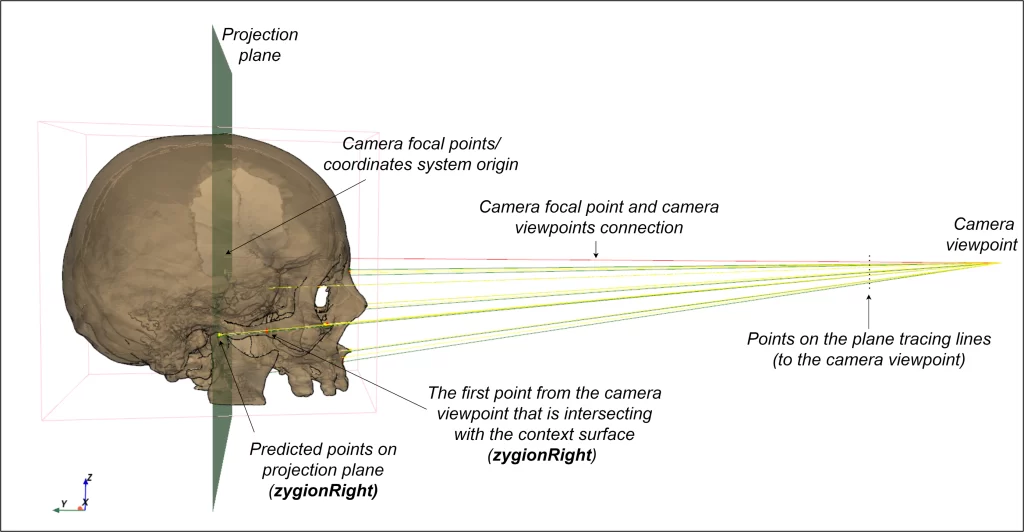

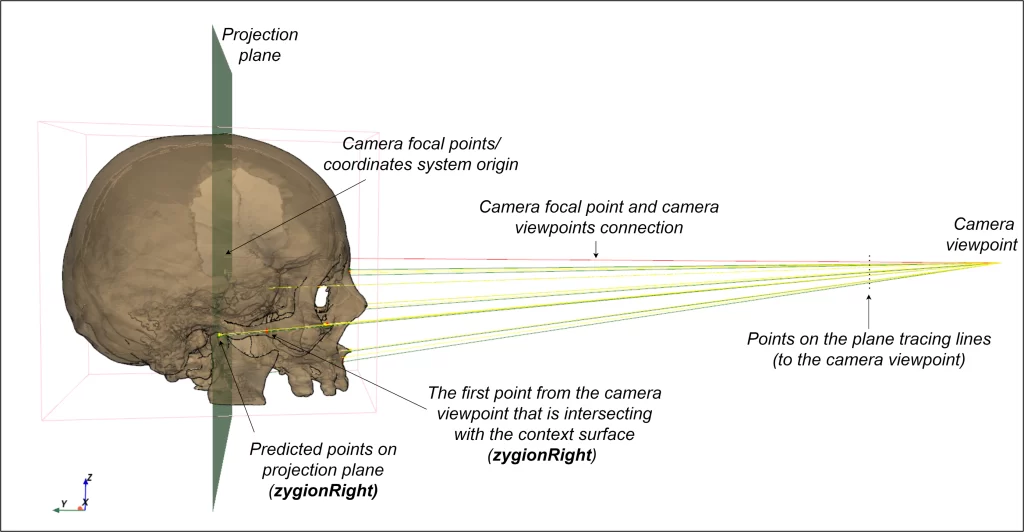

Leveraging the power of AI and Computer Vision, EasyFlow aimed to automate the reconstruction of personalized 3D anatomical models from CT scans and automate the 3D model cleansing process, along with the determination of clinical reference points.

The developed model would surpass human precision and drastically reduce processing time, thanks to EasyFlow’s cutting-edge MLOps services.

Implementation

EasyFlow’s team, equipped with their advanced MLOps capabilities, tackled the challenge of working with complex medical data that often featured pathologies.

Preprocessing the data to prepare it for analysis required substantial expertise. Despite the complexities, the team’s dedication and medical expertise, combined with MLOps practices, helped kick-start the innovative project.

The resulting AI model, integrated with EasyFlow’s MLOps services, significantly outperformed human specialists in both accuracy and speed.

The laborious 3-hour manual task could be completed in an astonishingly fast 45-60 seconds.

The model data was then seamlessly integrated into Ortho Baltic’s “Medical Implants Customization Engine” (MICE) software, which facilitated preoperative planning for personalized implant production.

Outcomes

The collaboration between Ortho Baltic and EasyFlow’s MLOps services produced a groundbreaking solution that streamlined the development of patient-specific implants.

By automating the data reconstruction and cleansing processes, the model not only reduced the workload for specialists but also minimized the risk of human error, ensuring greater precision and consistency.

The successful implementation of the AI-powered pre-surgical system, coupled with MLOps expertise, heralded a significant step forward in the field of personalized medical devices.

It contributed towards improving patient care and, in the future, could play a pivotal role in advancing Industry 4.0 in the mass production of individually tailored medical devices.

Conclusion

The successful collaboration between Ortho Baltic and EasyFlow showcases the transformative potential of machine learning and AI in the healthcare industry.

By automating pre-surgical processes and improving precision with MLOps practices, the developed AI-powered solution promises to enhance patient care, revolutionize medical device production, and pave the way for more sophisticated personalized medical technologies in the future.

Curious About The Above Solution?

Chat with Vejūnė and explore your possibilities without any commitment.

Vėjūnė Krašinskienė

Chief Operating Officer

Book a no-obligation free consultation with our expert.