Artificial Intelligence (AI) has embarked on a transformative journey in the healthcare industry, promising revolutionary improvements in diagnostics, patient care, and medical decision-making.

However, as the potential of AI in healthcare continues to grow, so do the challenges associated with deploying these technologies responsibly and securely.

This is where MLOps solutions for healthcare, a multidisciplinary approach to machine learning operations, comes into play.

Understanding MLOps for Healthcare

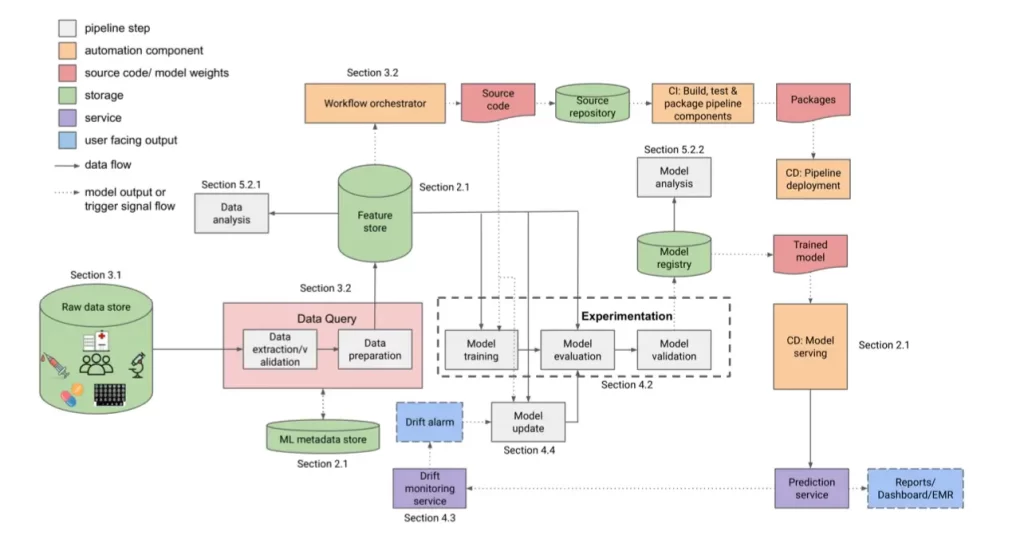

MLOps, short for Machine Learning Operations, is an emerging discipline that focuses on streamlining and optimizing the development, deployment, and maintenance of machine learning models.

While MLOps has broad applications across various industries, its importance in healthcare cannot be overstated.

MLOps for healthcare, often referred to as “MLHOps,” acknowledges the unique complexities and requirements of the medical domain.

It encompasses the entire AI lifecycle in healthcare, from data collection and preprocessing to model development, deployment, monitoring, and continuous improvement.

Why is MLHOps Essential in Healthcare?

The healthcare sector demands a higher degree of responsibility, trustworthiness, and accountability when implementing AI systems. MLHOps addresses several critical aspects that are specific to healthcare:

- Data Quality and Bias Mitigation: Healthcare AI models heavily rely on data, making data quality a top priority. MLHOps includes strategies for ensuring data accuracy, completeness, and fairness. Bias mitigation techniques are crucial to prevent discrimination in healthcare AI, especially in decisions related to patient care.

- Interpretability and Explainability: In healthcare, the “black box” nature of AI models is unacceptable. Interpretability and explainability methods help make AI decisions transparent and understandable, which is essential for gaining the trust of healthcare professionals and patients.

- Privacy and Security: Protecting patient data and ensuring cybersecurity are paramount. MLHOps incorporates robust security measures, data anonymization techniques, and strict compliance with healthcare privacy regulations.

- Algorithmic Fairness: Preventing bias and ensuring fairness in AI models is a fundamental ethical requirement. MLHOps integrates fairness-aware machine learning techniques to reduce disparities in healthcare outcomes.

- Deployment and Monitoring: Continuous monitoring of deployed AI models is vital to detect data drift, maintain performance, and respond to issues promptly. Proper deployment practices and cybersecurity measures are essential for real-world implementation.

- Regulatory Compliance and Accountability: Healthcare is a highly regulated industry. MLHOps ensures that AI systems comply with healthcare regulations and standards, while also maintaining accountability and transparency throughout the pipeline.

- Education and Communication: Educating healthcare professionals, patients, and stakeholders about AI systems is critical. Transparent communication fosters trust and responsible AI adoption.

- Continuous Improvement: The field of AI and healthcare is continuously evolving. MLHOps encourages organizations to seek opportunities for improvement, explore advanced techniques, and adapt to emerging challenges.

Real-Life Example of MLOps in Healthcare: Ortho Baltic Case Study

Ortho Baltic collaborated with EasyFlow to develop an automated data-driven model for implant production, reducing human error and processing time.

Ortho Baltic, a leading orthopedic device manufacturer in Europe, embarked on a transformative journey to streamline the development of patient-specific implants.

Traditionally, engineers manually reconstructed 3D anatomical models from CT scans, a time-consuming and error-prone process.

The Challenge

CT images often contained noise from metal artifacts, complicating anatomical landmark identification.

The Solution

Ortho Baltic partnered with EasyFlow, an AI and Computer Vision expert with top-notch MLOps services, to automate 3D model reconstruction and data cleansing.

The Results

The AI-powered solution significantly outperformed human specialists, reducing a 3-hour task to a mere 45-60 seconds.

This innovation enhanced precision, minimized human error, and paved the way for more personalized medical devices.

This real-life example demonstrates how MLOps can revolutionize healthcare by automating processes and improving precision in personalized medical device production.

The Promise of Responsible AI in Healthcare

Implementing MLHOps in healthcare is not just a matter of best practices; it’s a moral and ethical obligation. Responsible AI in medicine can revolutionize patient care, improve diagnosis accuracy, optimize treatment plans, and reduce healthcare costs. It can also aid in medical research by identifying new patterns and insights in vast datasets.

Furthermore, AI can augment the capabilities of healthcare professionals, providing them with valuable decision support tools that enhance their clinical expertise. It can assist in early disease detection, predict patient outcomes, and streamline administrative tasks, allowing healthcare providers to focus more on patient care.

Conclusion

MLOps for healthcare represents a critical framework for the responsible deployment of AI systems in medicine.

By addressing the unique challenges and considerations specific to healthcare, organizations can leverage the power of machine learning to improve patient outcomes while upholding the highest standards of ethics, security, and trustworthiness.

As AI continues to advance in healthcare, embracing MLHOps is not just a choice but an imperative. It is the path to a future where AI works seamlessly alongside healthcare professionals, enhancing the quality of care and ultimately saving lives.

In the realm of healthcare, MLHOps is not just an operational framework; it is the key to unlocking the full potential of responsible AI.

Not Sure How AI Can Help Your Business? Let’s Talk!

Lukas Vaznelis

Business Development Manager

Book a no-obligation free consultation with our expert.